Nicro, Croatia

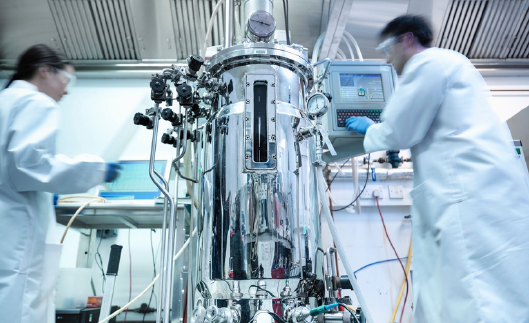

Advanced bioprocess control

A typical indicator of fermentation progress is the lack of dissolved oxygen in the media which gives an estimation of the process duration.

Optical density and metabolites may also be monitored for a better insight into the process. Concentration of metabolites would usually be measured off-line with time consuming chromatographic techniques and therefore would require samples. This can also bring a potential risk of contamination and lead to the loss of a valuable batch.

Nicro combined their competencies together with BIOCentre and Endress+Hauser to provide a complete packaged solution for fermentation processes.

The results included safe operation and time saving thanks to in-line process monitoring of metabolites without the need for sampling Improved process control leading to optimised production and increased yield Complete packaged solution for fermentation.

Find out moreMake Smarter Decisions

Return on investment

after 35 fermentation processes

Improved process control

leading to optimised production and increased yield

Safe operation

and time saving thanks to in-line process monitoring

Limited risk

of contamination

What our customer said

"While on-line monitoring the bioprocess I could pinpoint a time when bacteria switched from one carbon source to the other – the optimal time point to introduce feed and ultimately increase yield."

PhD Adriana Lepur

Head of Microbiology Laboratory BICRO BIOCentre Ltd, Zagreb, Croatia

Get in touch

We can help you to make smarter decisions and achieve your goals sooner. Get in touch by calling 0161 286 5000 or fill in our form and tell us how we can help.