Effective process monitoring

Meet your decarbonisation challenges with our hydrogen and carbon capture solutions

Process-critical instrumentation and solutions from Endress+Hauser help you to optimise your plant operations and reduce carbon emissions.

As the world seeks to achieve net zero, carbon capture and the use of hydrogen are becoming more widespread, and effective monitoring of these processes is essential.

With help from Endress+Hauser you can measure critical process points remotely, even under high pressure or extreme temperatures, with SIL certified devices; saving time, optimising safety and meeting environmental standards.

Providing fuel for thought

With potentially hundreds of hydrogen and carbon capture plants due to be built in coming years, instrumentation has a key role to play in ensuring processes are safe and optimised. We recently hosted a webinar in conjunction with Industrial Plant & Equipment focusing on improving the safety.

Read about it in the publication

Register to watch the webinar

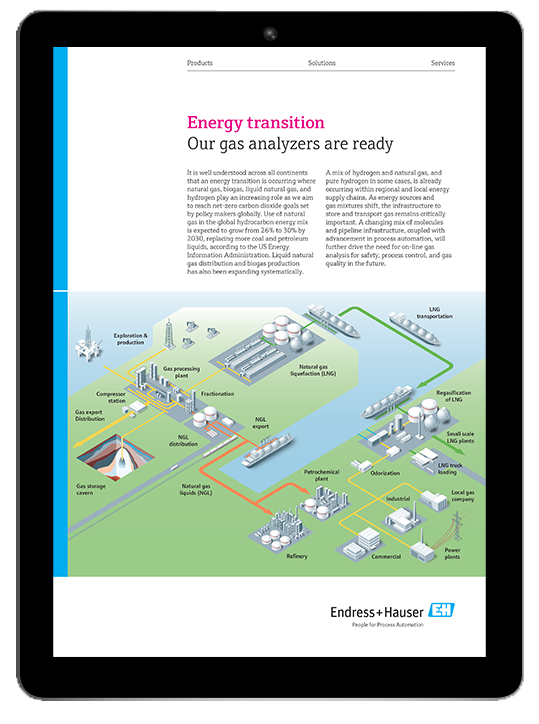

Navigate the evolving energy transition

An energy transition is occurring; natural gas, biogas, LNG and hydrogen play an increasing role as we aim to reach net-zero. Advances in process automation will drive the need for on-line gas analysis for safety, process control and gas quality. Endress+Hauser’s gas analysis portfolio incorporates the powerful measurement technologies of tunable diode laser absorption spectroscopy (TDLAS), quenched fluorescence (QF), and Raman spectroscopy.

Download our gas analysers brochureGet in touch

We can help you to make smarter decisions and achieve your goals sooner. Get in touch by calling 0161 286 5000 or fill in our form and tell us how we can help.